An Austrian leading flour mill boosted its bulk logistics by the implementation of a Daxner-Truck loading silo system. The new system, which loads wheat and rye flour into silo trucks, yields various benefits in terms of storage capacity, loading speed, loading autonomy and cost efficiency.

Description

Project goals:

Large storage capacity

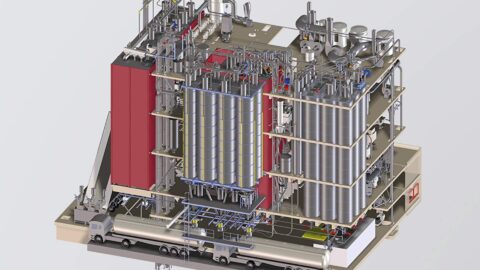

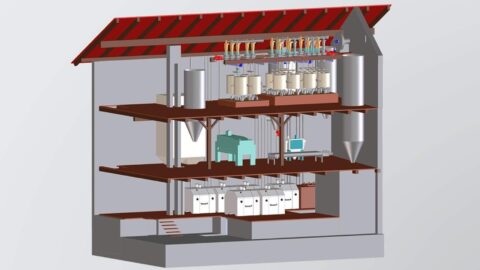

The truck loading silo system mainly consists of eight round silos of the same size, arranged in two rows of four each. Each silo’s storage capacity is about 90 tons, consequently the Pfahnl mill’s storage rose up to a total of 720 tons, whereby the growing demands and requirements of flour and bakery ingredient specialists can be easily met.

Short loading time

The system achieves a high loading speed: Within just 5 minutes, 25 tons of flour can be loaded. This is possible due to an optimal silo discharge design and flour fluidization which is carried out by a fluidization bin discharger. This guarantees not only secure discharge but also a very high loading performance. Moreover, a pneumatic docking system ensures that the loading device docks tightly to the filling nozzle of the silo truck, in order to realize a completely dust-free loading.

Absolute loading autonomy

Another advantage is the loading autonomy: No special staff is required for loading the silo trucks, since this can be done by the driver himself/herself. This is enabled by a weighing system consisting of two bridge scales in a coupling design. The total length of 33 meters allows the silo truck to stand entirely on the scale when any load cell is filled. The intelligent controls system allows independent, order-related silo truck loading by the driver. The target weights are dosed through the silo discharge flap, using a variable-speed drive in coarse or fine flow.

Highest hygienic design requirements

The truck loading silo system also meets highest requirements of the foods industry in terms of quality and hygiene. The flour is pneumtatically conveyed from the flour homogenization through a conveyor pipe (distance about 40 m horizontal and 40 m vertical) into the loading silos. In order to meet the requirements of the quality assurance, a sifter and an in-line impact machine check the flour for contamination and pests. A stainless-steel pipe system runs in free fall from all eight silos to a central loading device, therefore product contamination can be prevented.

Furthermore ATEX guidelines are also considered, so the system is protected against explosion by pressure relief with bersc disks. Jet filters with clean-air-side suction fans have been installed into the silos for dust collection.

Exact retraceability

In order to ensure complete traceability the customers receive a delivery note with every delivery on which the EAN 128 code is printed. This code identifies the flour. Also quality criteria such as the HACCP-IFS standards are fulfilled to 100 percent.

Key components

for this solution

Sounds interesting?

Let us know.

Send us your inquiry and a technical sales person is calling you back to talk about your projects or find a DAXNER partner company around you.